This picture represents three generations of quarriers of the Goshen Schist Formation in Cummington MA. From right to left you have: Rick LaFontaine, Almond Streeter, Jonathan Cranston, and Alan Streeter (Almond’s Son). The Streeter family owned the land the quarry is located on dating back to the mid 1800’s and frequently quarried the schist for land improvements and even to sell at times. In the early 1980’s Rick and his wife Sharyn officially started Sugarledge Stone Quarry and began a quarrying operation at what is now the existing site. Rick and Sharyn operated the quarry for 20 years when they sold the business to Jon and Carrie Cranston (Almond’s Daughter). Jon and Carrie operated the quarry from 2004 until 2023 when they sold to Bryce Ribken.

The Beginning

Things were done a little differently back in the day. Farm tractors, farm trucks, and a little Yankee ingenuity was how the people in these hills survived. A hard day of work didn’t count if you weren’t taking a little risk. These were the days before big Cat excavators and Volvo loaders. To get a large slab out of the ground and onto a truck took seriously hard work, a touch of good luck, and some careful planning. The Streeter’s were farmers first and worked hard to keep their family farm in business. Historically, farmers and rocks don’t exactly get along, so much of the stone removal was in an effort to clear fields and improve the farm’s productivity. Almond and the Streeter family are the origins of stone quarrying here in Cummington, and played an instrumental role for both Rick and Jon in developing Sugarledge Stone Quarry as we know it today. His close involvement with Rick and Jon left a legacy of the Hilltown values: hard work, frugality, and ingenuity.

The Idea

In the early 1980’s Rick and Sharyn LaFontaine entered into an agreement with Almond Streeter to start a quarrying operation on the Streeter Farm. . . Sugarledge Stone Quarry was born!

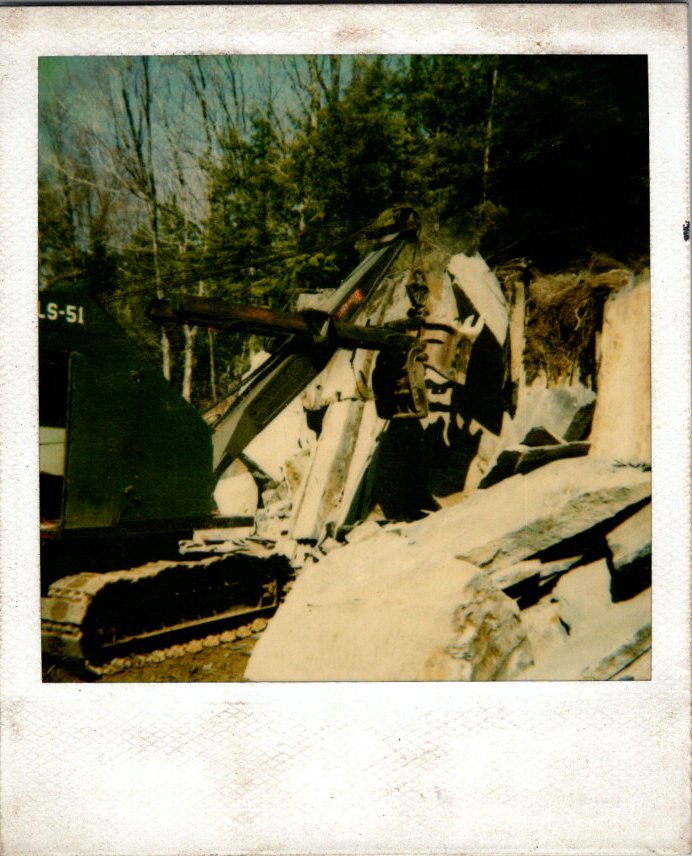

Rick built up a small team of miners and introduced new processes and methods to extract the stone. This included the site’s first excavator (a John Deere that is still in use in the quarry to this day), an iconic LINK-BELT shovel (on loan from Almond), and some other more novel equipment.

As Sugarledge Stone Quarry blossomed into a nice local business a foundation was built for the years to come. The original teams set the precedence for high quality work, good service, and a dedication to continued improvement.

The Processor

One of the more profound additions to the quarry operation during this era was the Sugarledge stone processor. This contraption was a collaborative design between Rick, Almond, and Richard Doty (uncle Richy) and was built cooperatively by Rick, Almond, Richard Doty, and Jon. This work station is the source of all the wall stone, palletized flagging, and precursor stone for the thin veneer.

The Next Level

In 2004 a young Jon and Carrie Cranston bought Sugarledge Stone Quarry from Rick and Sharyn LaFontaine. Jon brought his exceptional mechanical and fabrication skills to bear as he expanded and upgraded the equipment used in the quarry. Carrie brought excellent organizational and administrative skills to the table in order to manage the big picture functioning of the business.

As in all ventures, it takes a team of great people to make it all happen.

Can’t forget the pugs. . .

Archie

Chester

As many long time customers will remember, the Cranston’s mascot has always been a pug. Both Archie and Chester were iconic elements of Sugarledge Stone Quarry. Whether stealing someone’s lunch or tagging along for a delivery.

Crusher

Early in Jon’s tenure as Sugarledge Stone Quarry’s owner he recognized the need to better manage the waste stone generated in the day to day production of the quarry. He experimented with hiring a mobile aggregate outfit but soon realized that was not reliable enough. Jon and Carrie took the leap to invest in a Cedarapids crushing and screening plant, which Jon repaired and upgraded to suit the crushing needs for the quarry. SRG was born!

John Henry Drill

Jon also introduced a much improved method for drilling the 16 foot holes required to blast the ledge face. The original machine was designed to drill in the vertical, but Jon modified the attachment to allow for horizontal drilling. This vastly improved the quality and speed with which ledge faces could be drilled and blasted.

Scale

Yet another improvement Jon brought to the operation of the quarry was a scale, which dramatically improved the accuracy in calculating quantities for customer orders.

Thin Veneer Saw

In 2018 Jon and team introduced the Thin Stone veneer saw. This opened a new avenue for utilizing the stone and offered our customers yet another way to incorporate the Sugarledge stone in their projects.

Refurbishing

Jon also brought his extensive skills in repair and maintenance to restoring the equipment he and Carrie had purchased as a part of the agreement with Rick and Sharyn. As you can see below, the equipment was looking as good as new after he got done with it.